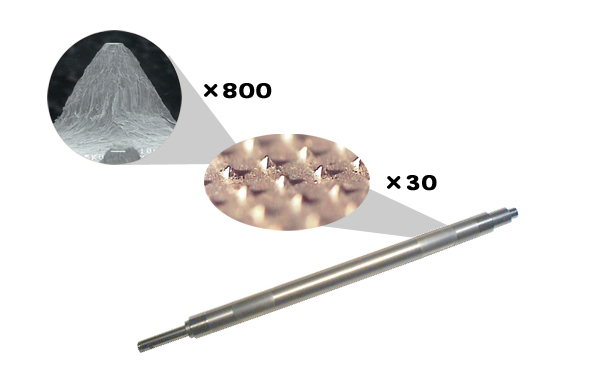

Capstan Roller

- It is abbreviation for Grip – Feed – Roller (G.F.R).

- It is the name of the simple and highly efficient roller for sheet conveyance which is manufactured by the plastic processing + special process method for having made full use of ultra-fine processing technology, and formed the minute and sharp projection directly on the circumference of a metal shaft.

- The mechanism of sheet conveyance

- Highly precise engagement conveyance without gap is realized by the thing which was formed with high precision, the tip of a minute and sharp metal projection is stuck in a sheet and grip powerfully.

- The features of G.F.R

- – Not to mention for paper and cloth, its power is demonstrated for both-way conveyance of the resin sheet on which its is easy to slide.

– Reliability and a long-life were realized by the effect of the processing method which the intensity and hardness of projection raise.

– High precision management of the degree of true circle at the tip of a projection was realized by the effect of the processing method which forms a projection gradually while making it rotate.

- The shape of a basic form of a projection – there are two types ; Pyramid type and Lozenge type Basic alignment of projections (there are three types of alignment and the shape of projection determined by its alignment)

-

Alignment Angle

Projection Form

Stuck Resistance

Conveyance Power

1

45°

Pyramid

1=2

1・2<31<2<3

2

0~90°

Pyramid

3

30°

Lozenge

- According to our experiences, the following points are summarized as notes on a design when you use G.F.R .

- Optimization of specifications of the projection for your application, operating conditions and the object media is the most important.

- *It is possible to perform a simple evaluation test with our evaluation equipment beforehand if you would lend out your media to us.

To optimize the hardness, intensity, load, etc., of a partner roller (Pinch Roller) - * It is possible to perform a simple evaluation test in measuring the size and depth of projection marks on the back side of media with our evaluation equipment beforehand if you would demand it.

To optimize the positioning of the media and projection based on equal distribution. - * It is possible to propose you the optimal value if you would demand it.

To align the height of a printing surface, a conveyance side and cutting plane. - Simplification of roller form in consideration of cost.

- G.F.R has been used most for Dye Sublimation Printer.

- To meet the customer’s severe demand and questions, we have been repeatedly testing for many years and as the results we have accumulated huge data and know-how.

With our experiences and know-how, we are confident that G.F.R would satisfy your requirements.

If the consultation with you from a design phase is possible, we would be of help more for your project.

- G.F.R cancels the four major poor printing factors.

- The four major poor printing factors

Color gap (Color registration)

Projection marks (convex pattern of the printing surface generated in the opposite side)

Streak pattern (streak lines on the both side of printing surface generated in the opposite side)

Jitter (horizontal striped pattern)

- A) The cause of color gap for Dye Sublimation Printer

- The main cause of color gap is lack of feeding power of projection roller.

- * As shown in the following (1) Normal projection marks (Good), if the marks remain in the same position after printing 4 times forward and backward, color gap will not take place.

- * To the contrary (2) Projection marks are shifted (NG), if the marks shifted to 2 pattern, 4 pattern the color gap will take place proportional to the quantity of the marks shifted. This phenomenon will arise owing to the balance in “Transportation Power of Roller < Printing Resistance.

- B) Cure

The following method may have conveyance power up and cure a color gap. - a. To change form and alignment of projection

b. To adjust the position of media and projection

c. Others using our know-how and data accumulated for years.

- Inquiry

- Price ?

- Price will be fluctuated from ten yen to million yen depending on size, material and quantity.

However, from the development phase of G.F.R it has been developed under the concept of ” Low Cost Process” as primary importance point, so we are confidence in price competitiveness.

Please let us have a chance to quote you. - Is there any track record ?

- Thanking for many customers in the past, the total quantity of G.F.R shipped out till end of 2006 became

more than 1.5 million pieces - How about correspondence to environment ?

- For metal shaft or roller normally lead contained in raw material and hexavalent chromium used for surface treatment become the problem for environment. However, since G.F.R mainly uses SUS material which does not contain lead and no need for surface treatment, it is reliable and can be used freely.

Furthermore, G.F.R is made of single metal material so it’s very easy to be recycled. - Can you measure its performance ?

- Yes, we can do it using our exclusive evaluation equipment developed uniquely and the tool microscope of high magnification.

Since we can measure its performance, we are able to reply to the customer’s demand such as “we want to have strong feeding power”, “we want to make a projection mark smaller”, “we want to specifically fix the amount of conveyances per one rotation”, so on. - Is the quality of material of roller restricted ?

- Any common metal which has ductibility with HV300 or less can be used without any problems.

We have also made G.F.R by titanium and aluminum for special application for the customer’s demand. - What is a projection specification with a track record ?

-

Inquiry

- Business Department No.4

- TEL : 81-3-6386-3507 / 81-3-6386-3509/ 81-3-6386-3510

- FAX : 81-3-6386-3523

- Mail : d1@sanko-mabis.com

- Items

- Needle Detector,Equipment for Salmon Hatchery,Assistive Device for Banking Services,Broadcast Equipment,Drilling Bit,Water Treatement Materials,Fish Processing Machine,Precision Metal Processing Parts,Surface Functional Improvement Technology,Electronic Components,Diamond,Japanese Foodstuffs, Daily Necessaries Overseas Delivery Service ,Rental Building