Improvement technology of the metal surface which adds a functional mirror surface to processing parts.

![]()

The Name comes from the Surface functional improvement technology

About SURFFIM

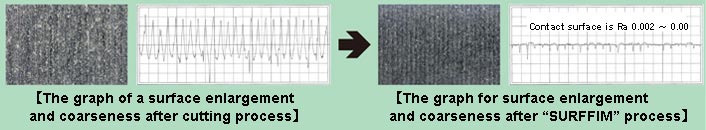

- “SURFFIM” is the improvement technique which is to make the micro roughness flat. Micro unevenness has been occurred the metalworking parts formed by cutting or carrying out grinding processing on the surface. This is processing surface like a just very fine metal file.

- In order to consume action power required for a slide and rotation by the resistance simultaneously with friction of a contact surface, for example, it results in needing excessive power supplies, such as electric power and oil pressure, and has caused the invisible and big energy loss. By “SURFFIM” process, resistance of sliding and rotation are sharply reduced by planarizing the detailed unevenness of material surface, mainly the side of a convex among uneven. Especially, in the case of a functional component which is combined with other parts and processed by sliding and rotation, it has caused a big resistance by the contact with a processing side, or the contact between processing sides in the same status.

-

The following effects can be acquired by improvement of such material surface.

∗Prolonged life cycle of parts

∗The improvement of an energy transfer loss

∗Miniaturization and weight saving of power supply

∗Energy-saving, cost cut

∗improvement of fast response performance

∗Improvement in sealing performance

-

【A variety of materials can be processed.】

- 「The difference between mirror surface process and “SURFFIM”」

- “SURFFIM” is able to process under the making a cutting process by NC automatic lathe. Besides, not only improving surface roughness, but also controlled and left the cavity surface element, it can reduce the contact area.

-

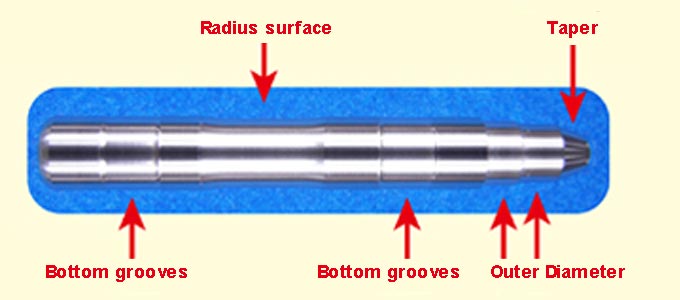

- 「A variety of machining shape can be processed.」

- The sliding performance of the processing surface is able to improve as requested.

-

- 「Features & Effectiveness of “SURFFIM”」

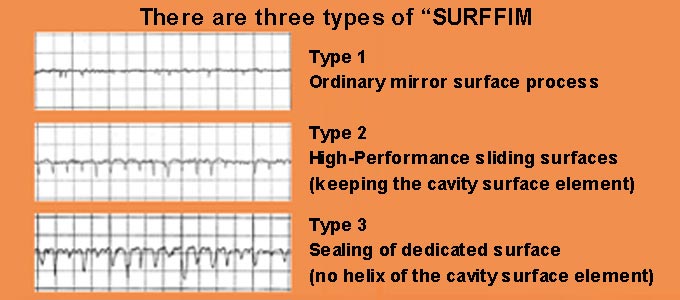

- 1. By processing mirror surface on the process surface, sliding resistance is dramatically in better improvement due to the contact of functional parts mainly.

- 2. Outstanding effect on sliding surface for rotation direction.

- 3. While making the uneven convexity to flat, control the concavity value and this certainly reduces the contact area and improve sliding friction.

- 4. Since it is possible to fabricate micro oil reserve as wished, lubricity is excellent. By the original processing method which is not occurred in helix with oil reserve, sealing performance is outstanding

- 「To customer who got interested」

- “SURFFIM” is our sliding improvement technology which appends to processing parts.

Therefore, we are not selling a tool for it.Also, improvement method of processing surface is not disclosed for details.

We really appreciate if you understand this.

It becomes a business style which we receive the order, including processing fee as processing parts.

In case of testing performance evaluation by customer, we can discuss the detailed parts specifications through a trial production.

We can give you the best proposal to meet your demand.

- ※ “SURFFIM” which is processing of metal is a registered trademark of DAIAN.

Inquiry

- Project Department

- TEL : 81-3-6386-3509 / 81-3-6386-3510

- FAX : 81-3-6386-3523

- Mail : bj@sanko-mabis.com

- Items

- Rental Building,Diamond,Japanese Foodstuffs, Daily Necessaries Overseas Delivery Service ,,Needle Detector,Precision Metal Processing Parts,Surface Functional Improvement Technology